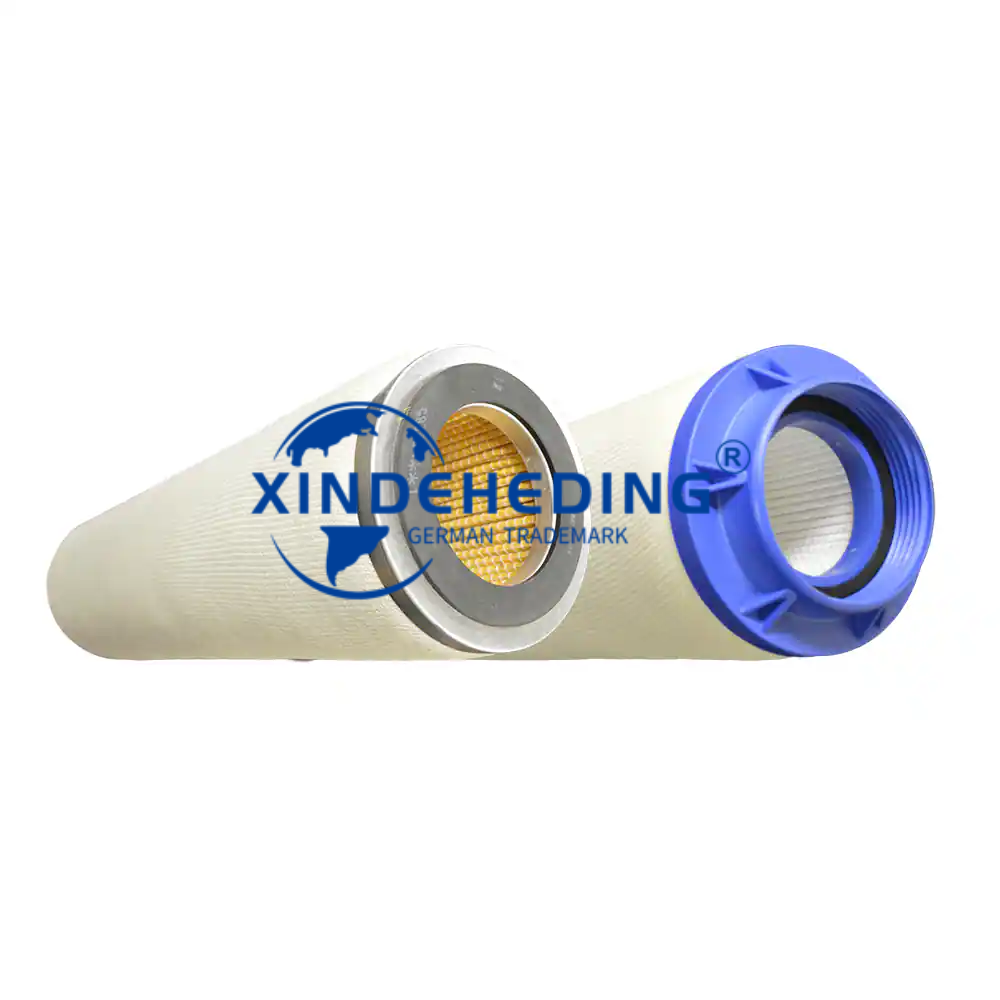

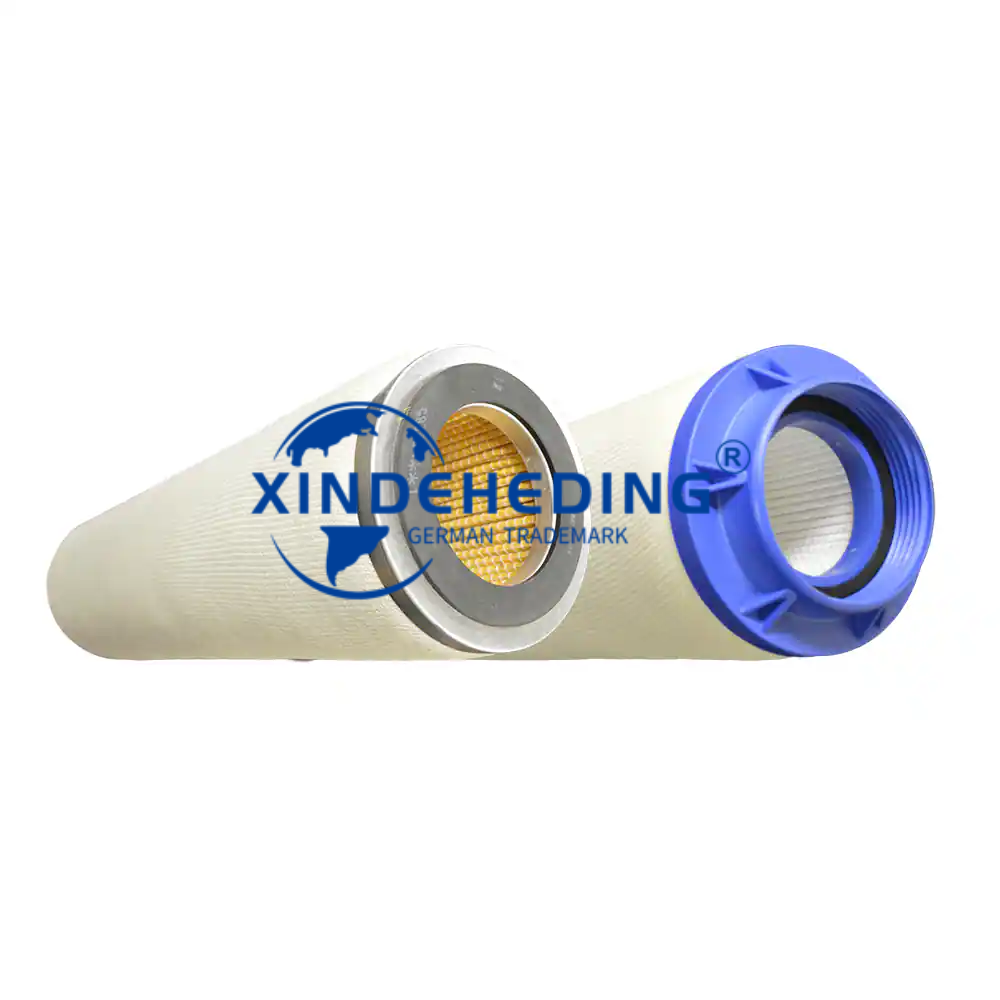

Replacement for Parker CLEANDiesel Coalescer cartridged are designed for separation of highly dispersed emulsified water particles and removal of particulate contaminants from diesel fuel.

As fuel is transported from the refinery to its point-of-use, it can quickly become contaminated from silica, pipe scale, and water condensate. These contaminants rapidly deteriorate fuel cleanliness far below engine manufacturers minimum for fuel cleanliness.

Replacement for Parker Velcon's DI coalescers in combination with DSO separators, contaminated fuels are cleaned to a level that meets stringent downstream fuel cleanliness standards for petroleum based diesel fuels.

The first stage in the DI coalescer removes particles through an inside-out flow and coalesces emulsified water into large droplets, which then fall to the housing sump. In the second stage, an outside-in process, the DSO separator creates a hydrophobic barrier to block the coalesced water droplets from flowing downstream of the housing. This multi-stage design assures the fuel is conditioned to a clean and dry state, ready for use.

Tiered Ratings

- Replacement for Parker Velcon's 4 micron coalescer combines leading-edge particle removal with world-class coalescing technology to provide optimal fuel cleanliness

- The 10 and 25 micron rated filter coalescer provides effective particle removal with industry proven coalescing technology.

Benefits

- Extended equipment up-time

- Reduced operating costs

- Reliable fuel injector performance

- Improved equipment up-time

- Reduced fuel system maintenance

Product Specifications

- All filter components compatible with petroleum based diesel fuels

- Downstream free-water level typically below 50 ppm

- Recommended change out pressure: 25 psid (1.7 bar)

- Buna-N sealing materials standard

- Maximum operating temperature: 150°F (65°C)

- 6” (15.2 cm) outer diameter

- DI - coalescer flow direction - inside to outside

- DSO - separator flow direction - outside to inside

| Filter Type: | Coalescer |

| Seal Material: | Buna-N |

| Micron Rating (µm): | 4 |

| Maximum Operating Temperature: | 65 °C, 150 °F |

| Maximum Burst Pressure: | 75 psi, 5.2 bar |

| Filter Construction: | Fiberglass |

| Changeout Pressure Differential: | 25 psi, 1.7 bar |

| pH Range: | Continuous Operation: 5 - 9 |

| Brand: | CLEANDiesel® |

| Flow Rate: | Depends on fluid viscosity and application. See brochure for more information. |

| Application: | Diesel |

| Application: | Diesel |

| End Cap Configuration: | Threaded Base |

| Length (inch): | 14.625 |

| Inside Diameter (inch): | 3.5 |

| Outside Diameter (inch): | 6 |

| Products | Application | Outside Diameter (inch) | Length (inch) | Filter Construction | End Cap Configuration | Micron Rating (µm) | Seal Material | Inside Diameter (inch) |

| DI-614D10TB | Diesel | 6 | 14.625 | Fiberglass | Threaded Base | 10 | Buna-N | 3.5 |

| DI-614D25TB | Diesel | 6 | 14.625 | Fiberglass | Threaded Base | 25 | Buna-N | 3.5 |

| DI-614D4TB | Diesel | 6 | 14.625 | Fiberglass | Threaded Base | 4 | Buna-N | 3.5 |

| DI-628D10TB | Diesel | 6 | 27.875 | Fiberglass | Threaded Base | 10 | Buna-N | 3.5 |

| DI-628D25TB | Diesel | 6 | 27.875 | Fiberglass | Threaded Base | 25 | Buna-N | 3.5 |

| DI-628D4TB | Diesel | 6 | 27.875 | Fiberglass | Threaded Base | 4 | Buna-N | 3.5 |

| DI-633D10TB | Diesel | 6 | 33 | Fiberglass | Threaded Base | 10 | Buna-N | 3.5 |

| DI-633D25TB | Diesel | 6 | 33 | Fiberglass | Threaded Base | 25 | Buna-N | 3.5 |

| DI-633D4TB | Diesel | 6 | 33 | Fiberglass | Threaded Base | 4 | Buna-N | 3.5 |

| DI-638D10TB | Diesel | 6 | 38 | Fiberglass | Threaded Base | 10 | Buna-N | 3.5 |

| DI-638D25TB | Diesel | 6 | 38 | Fiberglass | Threaded Base | 25 | Buna-N | 3.5 |

| DI-638D4TB | Diesel | 6 | 38 | Fiberglass | Threaded Base | 4 | Buna-N | 3.5 |

| DI-644D10TB | Diesel | 6 | 44 | Fiberglass | Threaded Base | 10 | Buna-N | 3.5 |

| DI-644D25TB | Diesel | 6 | 44 | Fiberglass | Threaded Base | 25 | Buna-N | 3.5 |

| DI-644D4TB | Diesel | 6 | 44 | Fiberglass | Threaded Base | 4 | Buna-N | 3.5 |

| DI-656D10TB | Diesel | 6 | 56 | Fiberglass | Threaded Base | 10 | Buna-N | 3.5 |

| DI-656D25TB | Diesel | 6 | 56 | Fiberglass | Threaded Base | 25 | Buna-N | 3.5 |

| DI-656D4TB | Diesel | 6 | 56 | Fiberglass | Threaded Base | 4 | Buna-N | 3.5 |

English

English