Sinter Plate Filter for Gas-Solid Separation,pure surface filter

Sinter plate is the most important filtering element of sinter plate dust collector for gas-solid separation.

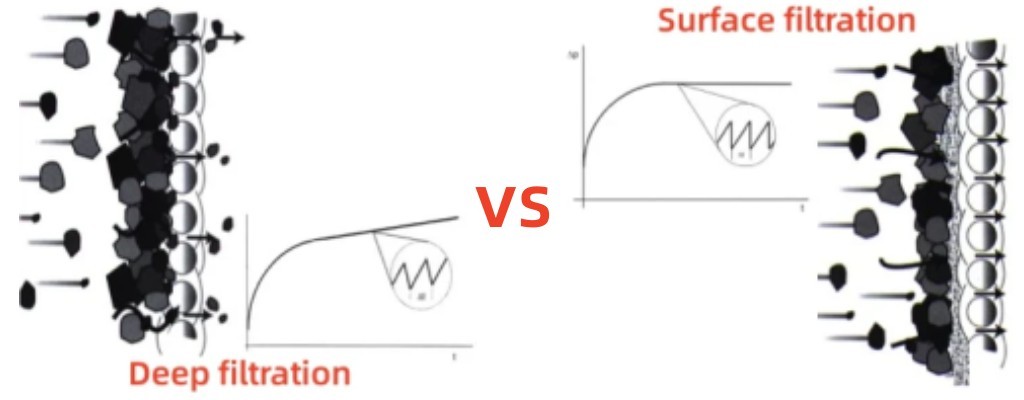

Sinter plate is made of special polymer based composite after compatibility matching and sintered in special high temperature furnace. After sinter molding, the matrix has irregular and fully connected micro-pores. Only the gas can pass the micro-pore, and the micro-particle dust is retained on its surface, thus achieving the dust removing and filtering effect. Moreover, the surface of the sinter plate is coated with reinforced PTFE resin membrane. This kind of resin membrane is featured by extremely self-cleaning function, and can effectively prevent dust cementation when it is working. Additionally, it can automatically discharge ash by adopting the gas back-flushing technique to ensure stable drag loss.

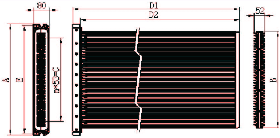

Most sinter plates have rectangular structure, and the filtering part has wavy plate structure to increase its effective area for dust removing and filtering.

Sinter plate filter

(XDHD) are specifically designed for high filtration efficiency and low pressure drop. The monolithic design is also very strong and durable, making it ideal for a variety of applications.

Product Advantages:

Longest service life of sintered plates up to 10 years

Long service life, relatively low maintenance and consumables costs

Optimized geometry reduces pressure drop

Increased pleats in each chamber significantly increase filter area

Constant pressure drop keeps airflow constant, helping to improve equipment efficiency

Surface filtration for high separation efficiency

Monoblock sintered plate design for compact rigidity

Suitable for abrasive dusts

Completely fiberless filter media, ideal for product recovery

Can be cleaned, recycled, and refurbished

Can be provided with anti-static or non-anti-static sintered plates

Can be installed from either dirty gas or clean gas side

Can be installed horizontally or vertically

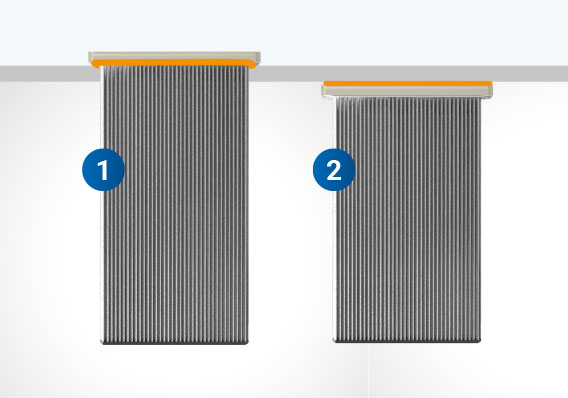

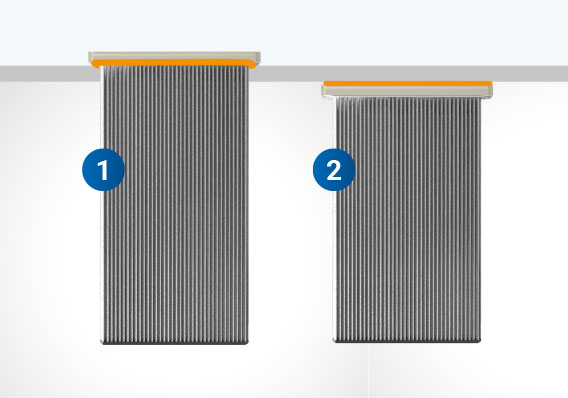

Direction of installation

Depending on the individual application and process requirements horizontal or vertical installation is possible.

1 Clean gas-side installationInstalling

the filter elements from the clean gas side enables optimal and clean access to the filter elements and provides highest possible protection for the personnel.

2 Raw gas-side installation

Installing the filter elements from the raw gas side usually allows a direct and optimal revision of the raw gas area. It requires no additional height above the filter system for servicing the filter elements.

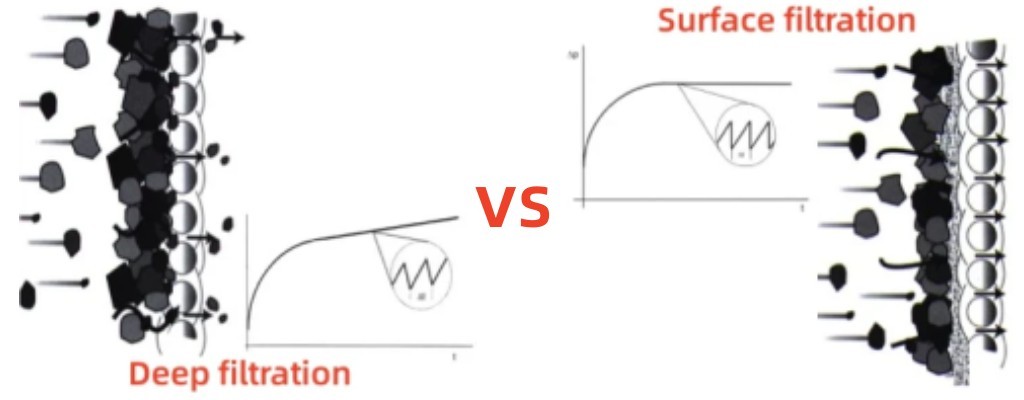

pure surface filter

The sinter plate filter have a PTFE coating on the PE basis, so do not need dust cake to block the other dusts.

When the pulse-jet working, the efficiency will not influenced by the original conditions.It is called surface filtration.

The advantages of Herding filters with surface filtration include:

High Efficiency Filtration: Surface filtration technology efficiently captures and separates particles on the surface of the filter media, providing effective filtration and removing fine particles effectively.

Low Pressure Drop: Surface filtration typically results in lower pressure drops compared to depth filtration, leading to reduced energy consumption and lower operational costs.

Long Service Life: Surface filters often have extended lifespans as they are less prone to clogging, and maintenance is relatively simple, minimizing downtime and maintenance expenses.

Wide Applicability: Surface filtration technology is suitable for various industrial applications, including dust collection, gas purification, liquid filtration, offering flexibility and versatility.

Versatility in Particle Capture: Surface filtration effectively captures particles of various sizes and shapes, ranging from fine particulates to larger particles, making it suitable for a wide range of applications.

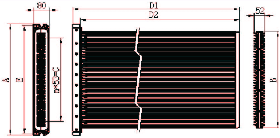

| Picture | Item No. | A | B | C | D | D₂ | E | n | Filter area |

| mm | mm | mm | mm | mm | mm |

| ㎡ |

| XDHD750-9 | 565 | 490 | 424 | 758 | 720 | 551 | 8 | 2.3 |

| XDHD1200-9 | 565 | 490 | 424 | 1203 | 1165 | 551 | 8 | 3.7 |

| XDHD1500-9 | 565 | 490 | 424 | 1495 | 1457 | 551 | 8 | 4.7 |

| XDHD750-18 | 1047 | 966 | 901 | 755 | 705 | 1035 | 17 | 4.7 |

| XDHD1200-18 | 1047 | 966 | 901 | 1200 | 1150 | 1035 | 17 | 7.6 |

| XDHD1500-18 | 1047 | 966 | 901 | 1500 | 1450 | 1035 | 17 | 9.4 |

English

English