Among filtration systems, the most universal filtration systems are particulate filtration and coalescing filtration. In our blog, we have already introduced lots of knowledge about dust filtration. It is time to move our attention to coalescing filtration.

Compared with particulate filtration, coalescing filtration usually adopts more fine glass fiber filter elements to remove droplets and aerosols. If you want to know more about coalescing filtration, then read the article below.

What are the coalescer filter and separator filter?

To separate liquid droplets and aerosols from both liquid and gas media, a coalescer and separator filter are utilized. Specialized materials such as micro-fiberglass, synthetic fibers, and thermoplastic resins are used in the production of coalescer filter components.

Each coalescer filter material has a range of filtering grades for various coalescer functions and media and is specifically designed to meet the requirements of the application.

Coalescer filters are used to separate different petroleum-based liquids, such as hydraulic fluid, jet fuel, and diesel, by removing water. This guarantees the best possible fuel efficiency and operation of industrial equipment, motor vehicles, generators, and aircraft.

Oil and water aerosols are also removed from compressed air systems using coalescer filters. Coalescer filters limit the buildup of lubricants, condensed water, and oils on pipes, joints, and fixtures by removing undesirable moisture from the airflow.

Coalescer filters accomplish this by ensuring maximum performance, extending the equipment’s useful life, and minimizing the need for upkeep and cleaning.

Coalescer filtration systems catch any solid particle debris that can contaminate your system since they work within the flow of air or liquid material. This helps keep your system from becoming clogged with dust, grime, and other debris.

To prevent clogging the coalescer and limiting the flow of air or fluid, it is crucial to make sure your system has the appropriate kind of filtration configuration.

A coalescer can function alone or be integrated into a more complex separation system, depending on the application and media being filtered.

How does the coalescer filter and separator filter work?

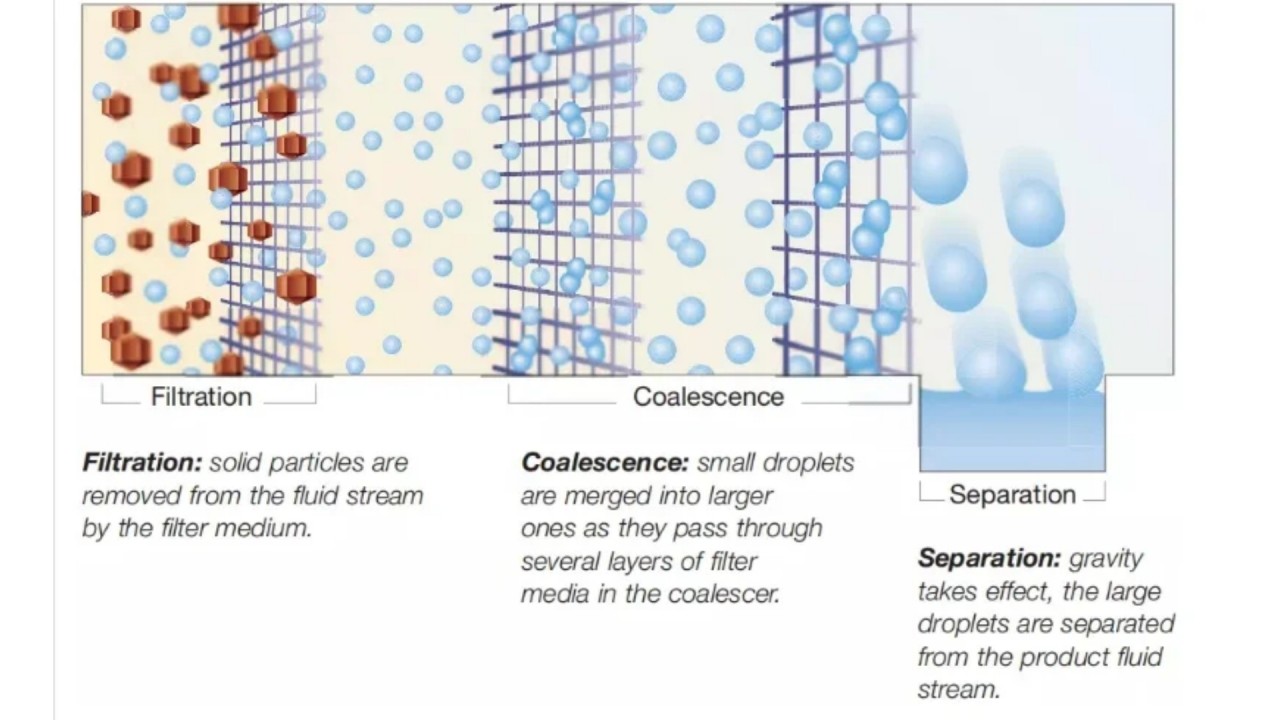

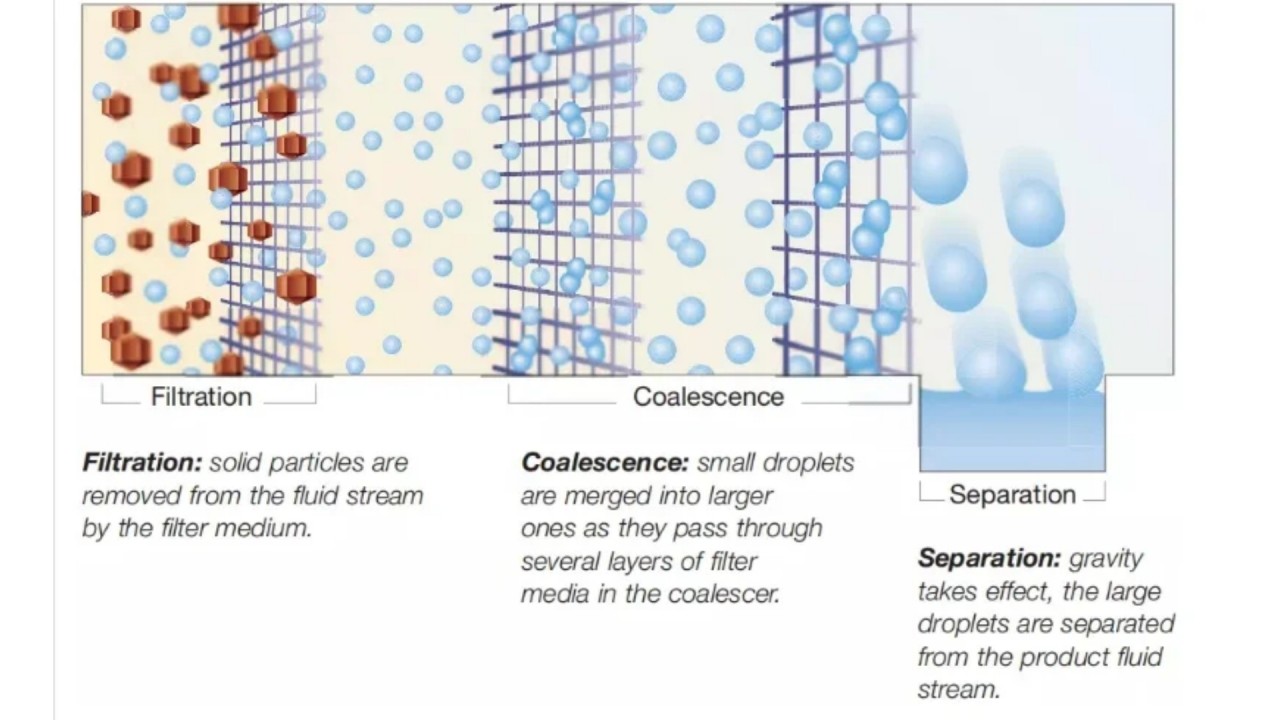

Different from traditional particulate filtration, which removes solids contaminants from gas or liquids. The coalescing filtration has two parts. It has two steps to remove undesired substances.

The size of the impurities you want to remove will determine how to select coalescing filters. Smaller particles may need interception and diffusion, however particles larger than one micron can often be removed with direct contact filtration. Coalescing filters work in a similar way regardless of the approach.

On the filter element’s fiber material, liquid droplets gather and coalesce at fiber intersections to form bigger droplets that are attracted to the filter element’s bottom by gravity. Droplets grow bigger and heavier as they accumulate and advance down the filter, eventually falling from the filter’s base into a drainage system.

Which applications need coalescing filtration?

Coalescer filters are used in a wide range of applications, including fuel filtering, petrochemical refining, oil and gas activities, and petrochemical operations. They can be employed in oil and gas refining systems to separate gas and liquid to create high-purity end products.

Additionally, coalescer filters are employed to safeguard oil and gas refining machinery against water vapor, which can corrode pipes, storage bins, and other vital pieces of machinery.

Coalescer filters are also useful for industrial air compressor applications where humidity and particulate matter can reduce system efficiency, fuel filtering in automobiles and aircraft, and natural gas dehumidification.

They can be utilized in practically any filtering system that needs to remove submicron liquid droplets and aerosols, including the cabin pressurization systems for airplanes.

What are the benefits of coalescing filtration?

Are you also curious about why coalescer and separator filter is so popular and preferred by many plants and industries? There is no doubt that it has lots of outstanding advantages and excellent abilities.

Lower pressure drop with a large surface area

Protection for the downstream equipment

High efficiency

Longer service time

Lower maintenance and operation costs

High capacity and high flow rate

How can coalescing help in the oil & gas industry?

Downstream filtration

Coalescers are used in the downstream oil and gas industry for product refinement. Filter elements can be employed at natural gas refineries to dehumidify natural gas and guarantee product purity before selling the product.

Systems that use gas-oil coalescers can clean natural gas by removing condensate and a number of natural liquids.

Additionally, by removing impurities like water vapor and sulfur with an efficiency as high as 99.98%, coalescing filters are actively utilized to avoid corrosion in downstream oil and gas assets like compressors, amine/glycol absorbers, turbines, and membrane filtration systems.

When positioned at a compressor’s outlet, coalescing filters can be utilized to collect lubricating oil from the device. Aerosols, particulate debris, dissolved hydrocarbon liquids, and slugs are some of the fluids that are fed into the compressor’s inlet and are removed by a filter element that is situated upstream of the compressor.

Petrochemical Industries

Prior to storage, water vapor, amine solutions, and sulfur can be phase-removed from petrochemical feedstock using liquid-liquid coalescers . The purity of the product is ensured by removing pollutants, which also stops industrial equipment from corroding.

Conclusion

Filtration is an important part of many industries, which they can not ignore. As one of the essential filtration systems, coalescing filtration is needed in many oil, gas, and liquid industries. It does fine filtration with 2 phases, coalescing the droplets and aerosols, then removing them.

We has years of filtration experience and designs and manufactures all kinds of filter products. We try to do our best in the water treatment field. We offer coalescer and separator filter series for diverse needs. If you are interested in our coalescer and separator filter, please feel free to contact us.

English

English